Custom Emblem Backings

Custom Emblem Backings

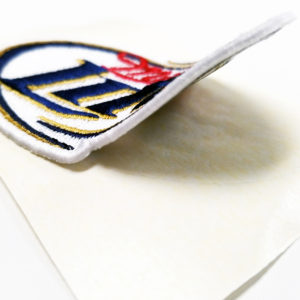

PennBond® Industrial BackingIndustrial backing is specifically designed to be able to withstand the Industrial Laundry process. Emblems with PennBond® backing can be either sewn or heat sealed onto garments. PennBond® is the recommended backing for emblems being used in the Rental Uniform Industry. Industrial adhesive backing has been tested for up to 50 wash cycles. |

Low Melt BackingLow-Melt backing heat seals at low temperatures without doing damage to the garment. Suitable for home laundry only, Low-Melt backing can be used in the majority of industries to heat seal emblems to apparel and accessories. Low Melt backing has been wash tested for up to 25 wash cycles. |

|

|

Heat Seal Notes & Tips

Heat Seal Notes & Tips

- Thicker Fabrics may require longer cycle times beyond the ranges

- Treated Fabrics finished with coatings, sizing or repellents may not allow for the proper heat seal bonding.

- Items made with leather, suede, nylon, synthetics, nylon-shell, interlinings, rubberized coatings, and reflective fabrics, such as jackets and luggage, may react poorly to heat seal temperatures depending on thickness, weave, texture and weight. IT is recommended that these fabrics be tested first, with possible heat seal time and temperature adjustments. In many cases, it may be better to have emblems sewn onto these materials.

To learn more about specific Heat Seal guidelines for each adhesives, visit our Technical Support Page.

Pressure Sensitive

Pressure Sensitive Velcro

Velcro